Introduction:

The semiconductor manufacturing industry is the backbone of the modern digital world,

enabling advancements in computing, communication, healthcare, automotive, and industrial

automation. However, behind this technological marvel lies a highly complex and resourceintensive production process that generates substantial amounts of process wastewater laden with

hazardous chemicals, heavy metals, and organic compounds. Treating this wastewater is not only

a regulatory mandate but a moral and environmental obligation.

1. The Nature of Process Wastewater in Semiconductor Manufacturing

Semiconductor fabrication involves multiple intricate steps such as photolithography, etching, doping, chemical-mechanical polishing, and cleaning. Each stage utilizes ultrapure water (UPW) and specialized chemicals like:

- Hydrofluoric acid

- Sulfuric acid

- Hydrogen peroxide

- Ammonia

- Solvents like isopropyl alcohol and acetone

- Heavy metals such as arsenic, copper, and lead

This results in a complex mix of toxic and non-biodegradable effluents, making wastewater treatment essential for safe discharge or recycling.

2. Importance of Wastewater Treatment in Semiconductor Industry

a. Environmental Protection

Untreated wastewater can contaminate surface and groundwater, disrupt aquatic ecosystems, and pose long-term risks to public health. Rigorous treatment mitigates the risk of:

- Soil and water contamination

- Bioaccumulation of toxins in food chains

- Destruction of aquatic life due to altered pH, temperature, or chemical exposure

b. Regulatory Compliance

Semiconductor plants are bound by strict environmental regulations such as:

- Environmental Protection Agency (EPA) standards

- Zero Liquid Discharge (ZLD) norms in several countries

- ISO 14001 Environmental Management Systems

Non-compliance can result in hefty fines, operational shutdowns, and reputational damage.

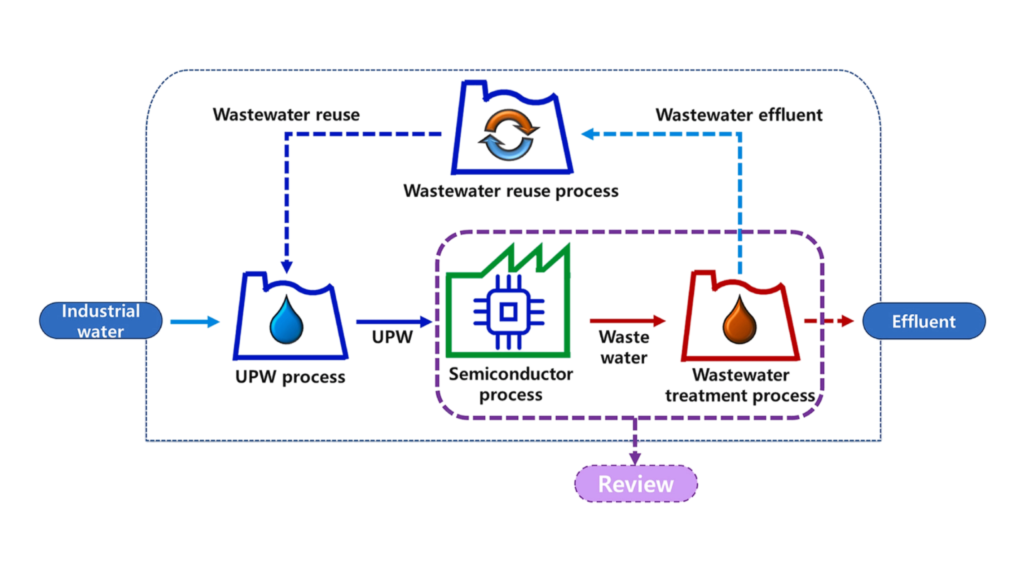

c. Operational Sustainability

Recycling treated water for reuse within the facility helps:

- Reduce freshwater intake

- Lower energy consumption for water purification

- Decrease dependence on municipal water supplies

This is particularly critical in regions facing water scarcity.

d. Corporate Social Responsibility (CSR) and ESG Goals

Proper wastewater management aligns with environmental, social, and governance (ESG)

initiatives, improving investor confidence and public perception.

3. Advanced Wastewater Treatment Technologies

Given the complexity of semiconductor effluents, conventional treatment alone is insufficient. Advanced and hybrid technologies are deployed for effective remediation:

a. Membrane Filtration Technologies

- Reverse Osmosis (RO): Removes dissolved salts and organics

- Nanofiltration (NF) and Ultrafiltration (UF): Effective for suspended solids, viruses, and organic molecules

- Electro deionization (EDI): Polishing method for ultrapure water recovery.

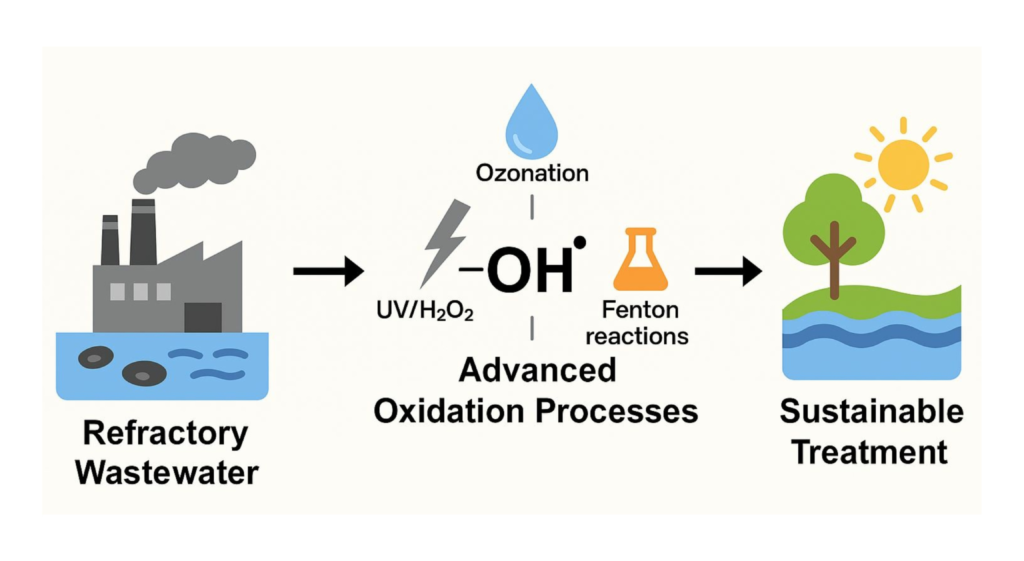

b. Advanced Oxidation Processes (AOPs)

- Utilizes hydroxyl radicals to degrade non-biodegradable organics

- Techniques: Ozone + UV, Fenton reaction, Hydrogen peroxide + UV

c. Ion Exchange Resins

- Targets removal of specific ions like arsenic, boron, and heavy metals

- Used for both cationic and anionic pollutants

d. Chemical Precipitation & Coagulation-Flocculation

- Converts dissolved contaminants into insoluble solids for easy separation

- Especially useful for metals and fluoride removal

e. Biological Treatment (where applicable)

- Anaerobic and aerobic processes may be used for biodegradable organics

- Integration with membrane bioreactors (MBRs) for compact design

f. Zero Liquid Discharge (ZLD) Systems

- Combines thermal evaporators, crystallizers, and condensers to ensure no liquid waste leaves the facility.

4. Safety Procedures in Wastewater Handling

Given the toxic nature of semiconductor wastewater, safety is paramount in treatment plants. Key safety practices include:

a. Automated Monitoring & Control Systems

- Real-time sensors for pH, ORP, turbidity, and specific ion concentration

- SCADA systems for operational control and emergency shutdowns

b. Chemical Handling Protocols

- Strict guidelines for storage, transport, and disposal of hazardous chemicals

- Use of corrosion-resistant materials in pipelines and tanks

c. Personal Protective Equipment (PPE)

- Chemical-resistant gloves, goggles, full-body suits, and respirators

- Regular health check-ups and training for plant personnel

d. Containment & Emergency Response

- Double containment for storage tanks

- Spill kits, neutralization systems, and fire suppression measures

- Periodic mock drills for chemical leaks or equipment failure

5. Environmental and Societal Impact

a. Water Resource Conservation

- Recycling of treated water minimizes stress on natural water sources

- Enables sustainable operations in water-scarce regions

b. Reduction in Carbon Footprint

- Energy-efficient systems (like low-pressure membranes, solar-powered units) contribute to net-zero goals

c. Ecosystem Preservation

- Prevents toxic bioaccumulation in rivers and marine environments

- Protects biodiversity and public health

d. Community Engagement

- Transparent disclosure of environmental impact

- Involvement in local water and environmental conservation initiatives

6. Future Trends and Innovations

The semiconductor industry is evolving toward Industry 4.0 and sustainability-driven models. Future trends include:

- AI and IoT-based smart water treatment systems

- Modular and containerized treatment plants for flexible deployment

- Green chemistry to reduce hazardous effluent generation

- Electrochemical treatment and plasma-based oxidation for emerging contaminants.

Conclusion:

The semiconductor industry’s quest for innovation must go hand in hand with environmental responsibility. Process wastewater treatment is not a peripheral activity but a critical component of sustainable semiconductor manufacturing. By investing in cutting-edge technologies, adhering to stringent safety practices, and fostering environmental stewardship, the industry can ensure that the chips powering tomorrow’s world are made in harmony with nature.

Good to learn about the vital role of wastewater treatment in semiconductor manufacturing. A crucial step

toward sustainability and process efficiency.

Thanks for sharing this. It’s easy to overlook the environmental side of tech production, but wastewater treatment clearly plays a huge role. Proper treatment systems help recover valuable materials, reduce water usage, and minimize the industry’s ecological footprint. This article does a great job of highlighting those critical aspects—looking forward to more such informative content!

This is something we rarely talk about, but it’s so important. Thanks for highlighting how wastewater impacts the semiconductor process.

It’s easy to overlook, but wastewater treatment is crucial in semiconductor manufacturing. Glad to see more awareness around this.

Essential point! Wastewater treatment is vital in the semiconductor industry to reduce environmental impact, meet strict regulations, and support water reuse in ultra-clean processes. A key move toward sustainable manufacturing.

A very relevant post! Treating wastewater in semiconductor production is essential for reducing pollution and ensuring cleaner, safer operations. Thanks for shedding light on this critical issue.